Functionality

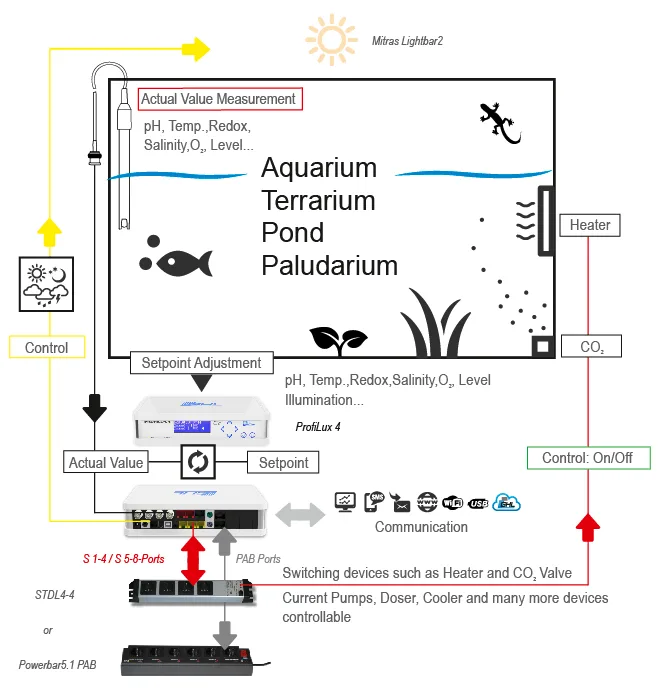

The following graphic gives you a rough overview of the functionality of the ProfiLux 4 Aquarium Controller. It also shows the interaction of the different system components.

Depending on the model and application, examples are: Water temperature, pH, conductivity, redox potential, alkalinity, level, flow, oxygen content, air temperature or humidity.

The water temperature is measured by the included temperature sensor. The controller controls heater, ground heater and cooling. The follow-up control with intelligent and self-learning interval switching always ensures optimal heating with pinpoint accuracy. Of course, a nightly decrease is programmable.

For measuring and controlling you need the following items in addition to the controllers (depending on the model):

- GHL powerbars e.g. Powerbar 6E-PAB for switching on and switching off consumers such as Solenoid valves, heating, cooling and pumps.

- GHL Sensors to measure various water values.

-

Possibly Expansion Cards or additional equipment depending on the desired application.

Sensors that are used for measuring various values such as Temperature, humidity, etc., are connected to either the ProfiLux 4 or to corresponding ProfiLux Expansion Cards. Each of these sensors are assigned to a control circuit where parameters such as Set-point, hysteresis, nocturnal change, etc., can be set.

With the desired values and settings set, each sensor can then be assigned to control a powerbar socket. For example, assigning a temperature sensor to a powerbar socket will result in that socket switching on/off based on the set probe conditions.

Features / Resources

The functional range of your ProfiLux 4 and, if applicable, your ProfiLux System is determined by the available Expansion Cards, sensors, PAB devices and LED lights.

The total of all available inputs and outputs in the ProfiLux system is referred to as resources.

Numbering and Display of Resources

All resources of the system are serially numbered by the ProfiLux Controller and this is always carried out the same way.

The resources of the ProfiLux are numbered firstly, followed by the respective PAB devices in order of their assignment such as Power Bars, Expansion Boxes, etc.

The numbering always starts with the internal resources of the ProfiLux, followed by the resources of the module cards in the expansion slots according to their order in the slots of the ProfiLux.

Then the resources of the first found and assigned PAB device will follow, after that the resources of the second PAB device, etc.

Operating Concept

The operating concept of the ProfiLux computer strictly differs between two sets of settings:

- Settings of functions such as e.g. pH set point, illumination run of a luminaire or behavior of pumps

- Settings of hardware such as the behavior of a switch socket (if this switching socket is assigned to a lighting, a timer or a temperature sensor) or the behavior of a 1-10 V interface (this interface should be assigned to a lighting or a pump)

This concept is extremely flexible because a function can be changed largely independently of the hardware assigned to it and vice versa the hardware can be changed largely independently of the function.

This concept allows you, e.g. to select a different socket for switching your tubular heater, while the corresponding temperature settings can remain unchanged.

Examples of Settings

For a better understanding, take a look at some setting examples that are commonly used.

- Setting the function: Set the desired set-point temperature, see also Sensor Settings-> Nominal value.

- Setting the hardware: Set the switch socket outlet (socket) to switch the heating element, the substrate heater and the cooling system (if present). See also System-> Socket outlet function.

How to set the Illumination?

- Setting the function: Set the illumination run as needed, see also Illumination-> Illumination run.

- Setting the hardware: Set which switch socket outlet (for non-dimmable luminaires), also see under System-> Socket outlet function, or which 1 – 10 V interface (for dimmable luminaires), also see under System-> 1- 10 V interface, or whether the Mitras Lightbar interface (when controlling a Mitras Lightbar) shall respond to this illumination run.

How to set the Level control?

- Setting the function: Set the operating mode and the behavior of the level sensor, also see under Level-> Control.

- Setting the hardware: Set which switch socket outlet (socket) is to be switched from the level control, see also under System-> Socket outlet function.

How to set the Current pump control?

- Setting the function: Set the pump groups and the current pumps, see also under Extras-> Current.

- Setting the hardware: Set which switch socket outlet (for non-speed-variable pumps), see also System-> Socket outlet function, or which 1-10 V interface (for speed-variable pumps), and see also under System -> 1-10 V Interface should react to the Pump.

How to set Dosing or Timer activities?

- Setting the function: First set the desired timer or dosing pump (note: only GHL Dosing Pump Unit 1st generation, GHL Doser 2 is controlled via PAB!), see also under Clock-> Timers or under Clock-> Dosing pump.

- Setting the hardware: Set which switch socket outlet (socket) is to be controlled by this timer or dosing pump, see also under System-> Socket outlet function.

- The ProfiLux 4 Controller and its components (ProfiLux 4 System) perform measurement, control, and control tasks based on your settings.

- There is no plausibility check of the settings you have made.

- The controller’s factory settings must be adapted to the requirements of your aquarium.

- You are solely responsible for the plausibility of your computer settings and its system components.

- The ProfiLux 4 Controller cannot replace the lack of expertise required for the maintenance and maintenance of an aquarium or terrarium.

- Never leave your aquarium unsupervised for an extended amount of time.

- The ProfiLux System can help you with a large number of tasks and display error conditions – but it cannot replace regular personal supervision and control.

- The maximum period of time without personal supervision depends on how long your aquarium / terrarium can survive even in the event of a fault without significant damage.

- Always remember that technologies can fail and therefore, malfunctions can never be ruled out!

Power failures, incorrect settings, damage (For example, by water or overvoltage) or simply an unexpected operating situation can lead to fatal damage.