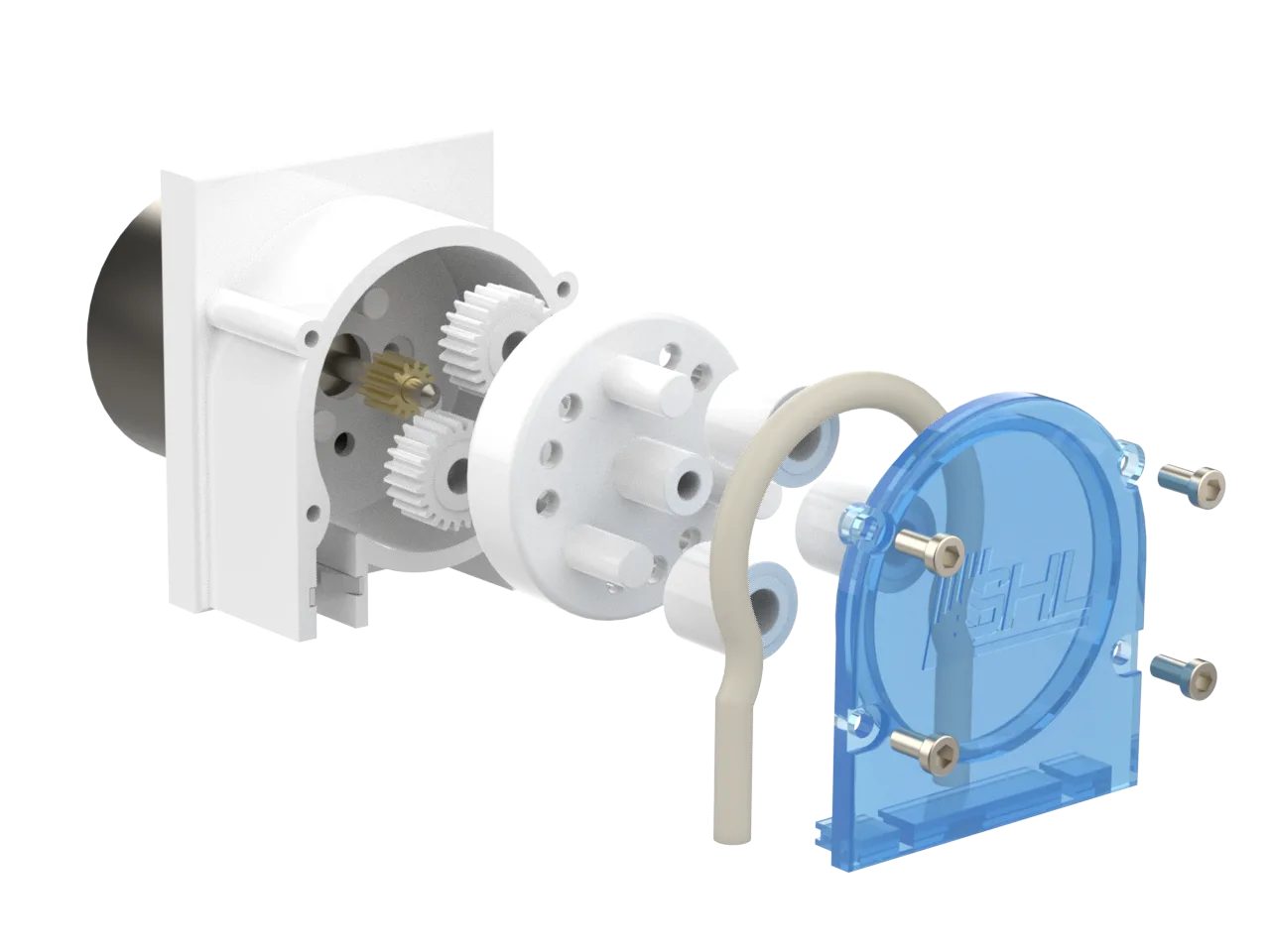

GHL Doser 3 Peristaltic Pump with Planetary Gear

Peristaltic pumps are among the most reliable and versatile pump types in dosing and fluid handling. They operate by pressing a flexible tube with rotating rollers or shoes to move liquid. While robust by design, the right lubrication often makes the difference in smooth operation, long service life, and low maintenance.

Not every pump should be lubricated

It is important to understand that not all peristaltic pumps are designed for lubrication. Certain pump models are built to run dry, where lubrication would interfere with their function. They must not be lubricated. Others, however, are factory-lubricated or require lubrication as part of regular maintenance.

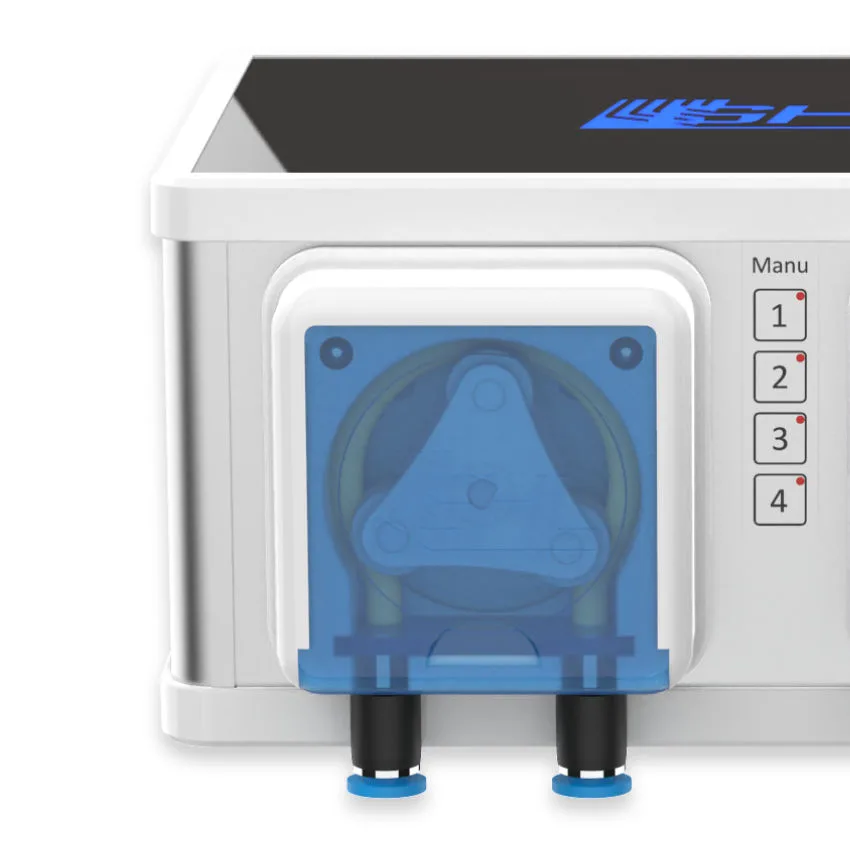

For example, GHL Doser 3 and GHL Doser 2/3 Maxi pump heads come sufficiently lubricated out of the box. Additional lubrication may be required after a long period of use, after cleaning, or when mechanical parts such as the tube or rollers are replaced.

What should be lubricated

Where lubrication is required, all moving and frictional parts should be covered with a very thin film of lubricant. This includes:

-

The rollers and especially the axes on which the rollers rotate

-

The tube in the contact area with the rollers

-

Any other surfaces subject to friction inside the pump head

If the pump contains an additional gearbox – for instance, the planetary gear of the GHL Doser 3 – lubrication is also essential for smooth and reliable operation.

What makes an ideal lubricant

Not every grease or paste is suitable for peristaltic pumps. Thin oils and sprays are flung off during operation and lose their effect quickly, while pastes that are too sticky can make the mechanics run sluggishly.

Some users also consider Vaseline (petroleum jelly). While inexpensive, it is not suitable for peristaltic pumps because petroleum-based products can attack plastics and rubber over time. This can lead to swelling, softening, or premature wear of tubes and other components – ultimately shortening the life of the pump instead of extending it.

An optimal lubricant should therefore have the following properties:

-

Specially developed for use in peristaltic pumps

-

Balanced viscosity: not too thin, not too sticky

-

Food-safe for safe handling during application

-

Stable across a wide temperature range

-

Provides long-lasting lubrication without affecting pump function

GHL Doser 2/3 Maxi Peristaltic Pump

A suitable solution

For these requirements, a high-performance silicone paste has proven to be the most effective choice. It provides durable lubrication, reduces friction and noise, and helps extend the lifetime of peristaltic pumps.

One example is the Silicone Lubricant for Peristaltic Pumps from GHL, which is food-safe, optimized for pump heads such as those of the GHL Doser 3 and Doser Maxi 2/3, and includes a practical brush for easy application.

Peristaltic pumps lubricant, 5mL

9,90 €9,90 €

Special high-performance silicone paste for lubricating peristaltic pumps, food safe

incl. brush for easy application

for GHL Doser 3, Doser Maxi 2 and 3, as well other suited peristaltic pumps