Description

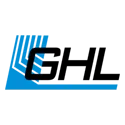

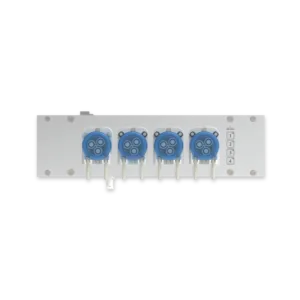

The Doser 3 EXT IL is the Industrial Line version of the GHL Doser 3 Extension, housed in an 8HU aluminum slide-in housing designed for the IP54-rated Industrial Line enclosure. The unit can also be installed in custom enclosures or cabinets. It delivers the same advanced technology and features as its standard counterpart in a form factor built for professional environments.

As an Extension unit, the Doser 3 EXT IL does not include its own control electronics. It connects via PAB (ProfiLux Aquatic Bus) to a Doser 3 SA IL, Doser SA IL, Doser Maxi SA IL, Doser 3 Maxi SA IL, or a ProfiLux controller (ProfiLux IL, ProfiLux 4, or ProfiLux 4e), which manages all dosing settings.

The 4 peristaltic pumps feature GHL’s PrecisionDrive technology — a custom-developed combination of 24V stepper motors and planetary gears, engineered and manufactured in-house. Each pump delivers up to approximately 80 ml/min with micro doses as small as 0.1 mL. Every pump can distribute up to 250 automatically spread micro doses per day or operate on up to 24 individually programmable dosing times. Continuous-run mode is also available, for example for operating reactors.

Multiple Doser 3 EXT IL, Doser EXT IL, Doser Maxi EXT IL, and Doser 3 Maxi EXT IL units can be combined via PAB for a maximum of 16 pumps per SA host or up to 32 pumps when connected to a ProfiLux controller. All GHL Doser generations (2.x and 3, standard and Maxi) are fully cross-compatible.

An optional GHL Logo Frontpanel IL (5HU) can be connected to the unit’s RGB logo port for visual system status indication.

Note: Power supply (24V) is not included and must be ordered separately. This allows the same unit to be deployed worldwide without country-specific variants.