Regarding precision and accuracy, nothing compares to our flagship, the GHL Doser. Hobbyists and Research Facilities have relied on it since 1999.

This and the ever-growing features added over time until today make the GHL Doser 2.2 a fantastic must-have for every Aquarium.

GHL Dosers do far more than extremely reliable and precise dosing

They can measure and automatically stabilize KH, Ca, Mg, and other parameters, and even manage fully automatic water changes and level control.

Also available as Industrial Line Version

Same proven technology and features in an aluminum slide-in housing designed for professional installations. Can be mounted in racks, cabinets, or the optional IP54-rated Industrial Line enclosure for harsh environments.

GHL Doser 2.2 Highlights

Ease of Use and Multiple Connectivity Options

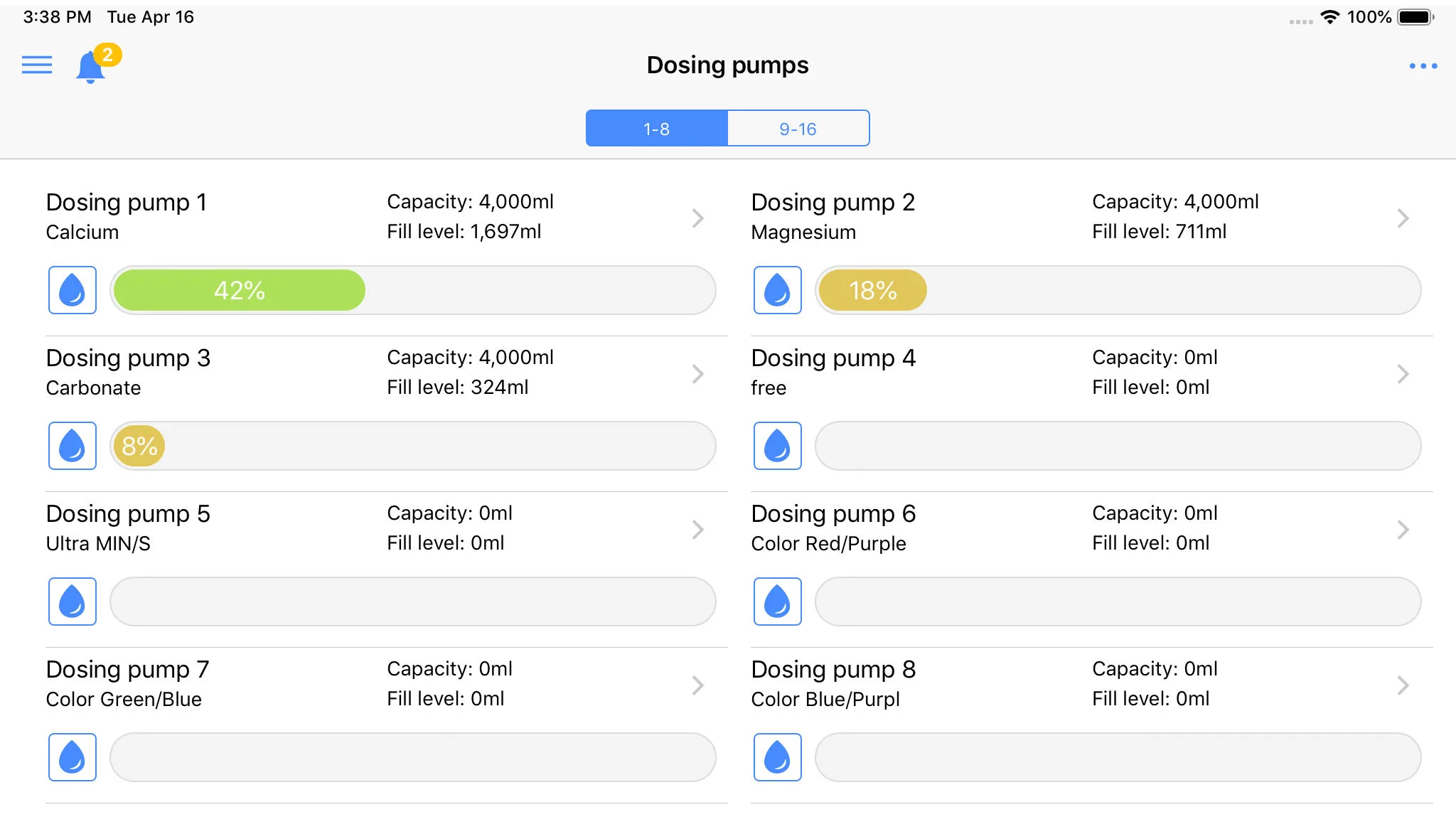

Easy and convenient operation with GHL Connect (app, web interface and cloud service) or GHL Control Center PC software.

Connect via WiFi or USB.

Precision and Flexible Dosing Schedules

Highly accurate 24 V stepper motors allow you to perform up to 150 micro doses per day. Precisely adjustable with a resolution of 0.1mL!

When determining the dosing times, you can choose your doses to be distributed automatically throughout the day — or up to 8 doses per day, individually set.

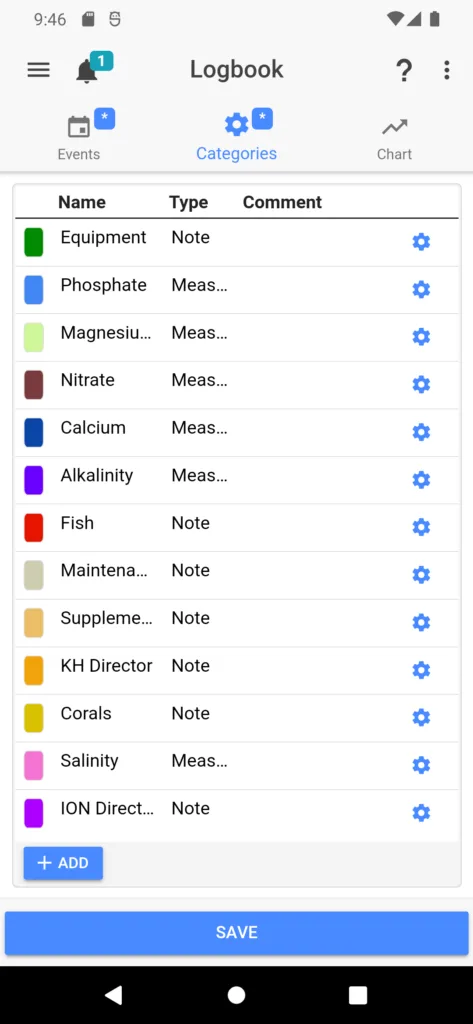

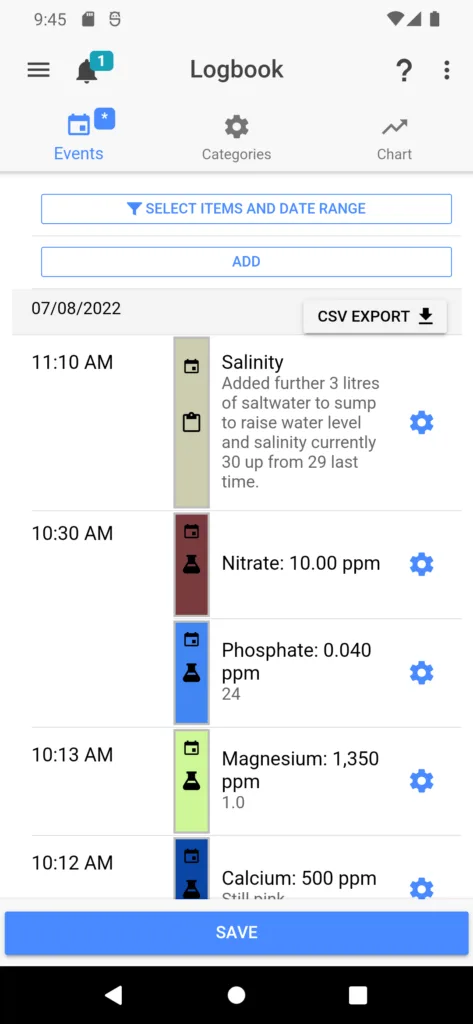

Tracking with the GHL Logbook

Keep track of all your aquarium-related events, set reminders, record past and current water parameters, and more with the GHL Logbook.

The GHL Logbook is your digital notepad for recording aquarium-related events, setting reminders, recording past and current water test results, and so much more.

„Have accurately set the dispensing at 0.1 ml and I am always impressed again how well it works“

Customer Review GHL Support Forum

Scalable to a Complete Dosing System

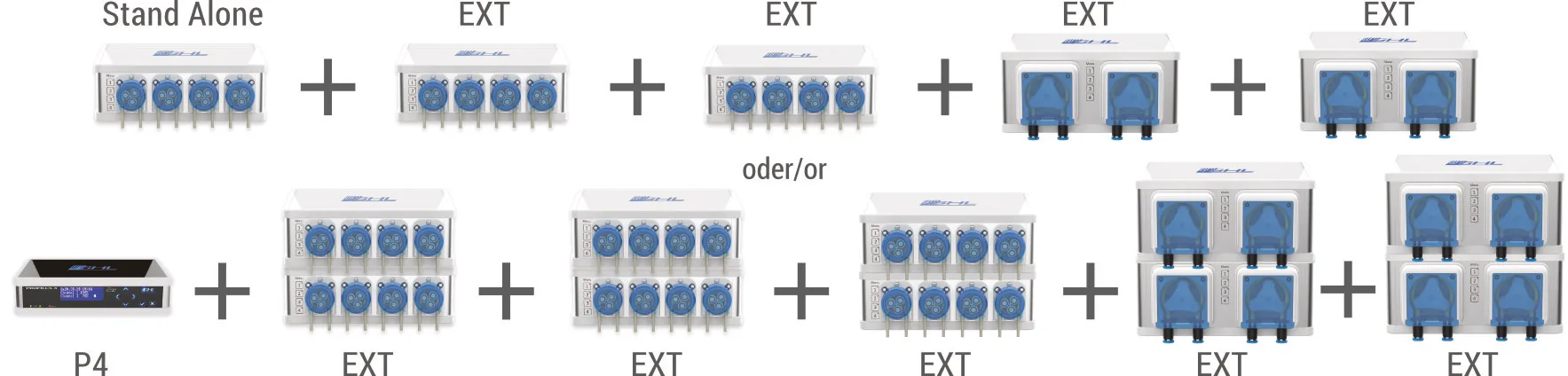

Need to control multiple dosing pumps? The GHL Doser 2.2 is the ideal solution, offering seamless expandability into a full dosing system. When used with a ProfiLux controller, you can independently manage up to 32 pumps—or up to 16 pumps when using any Stand Alone (SA) Doser.

The Stand Alone version includes integrated control electronics, allowing it to manage additional extension units (GHL Doser 2.x Extension or GHL Doser Maxi Extension).

Extension Dosers connect easily to either a Stand Alone Doser (GHL Doser 2.x SA or GHL Doser Maxi SA) or a ProfiLux 3 / 4 Controller.

All dosing pump settings can be configured with ease—locally or remotely—via the GHL Connect app, myGHL cloud platform, integrated web interface, or GHL Control Center.

Did you know that you can use the Stand Alone Doser also as an Extension Doser?

Simply activate the Extension Mode with a single click.

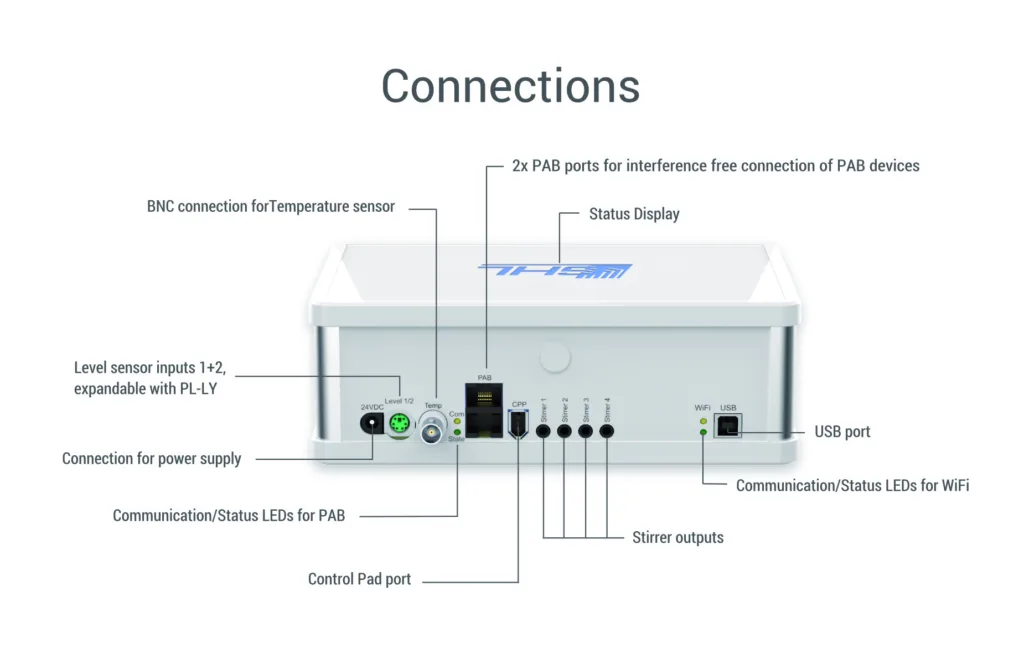

Stand Alone and Extension Doser Ports

GHL Doser 2.2 Stand Alone

Unlock the Full Potential of the GHL Doser 2.2 Stand Alone

Enhance functionality by connecting up to two level sensors to monitor the water level in your aquarium or sump, along with a temperature sensor to keep track of water temperature.

For optimal dosing accuracy, pair the system with our Magnetic Stirrer to ensure liquids are thoroughly mixed before each dose.

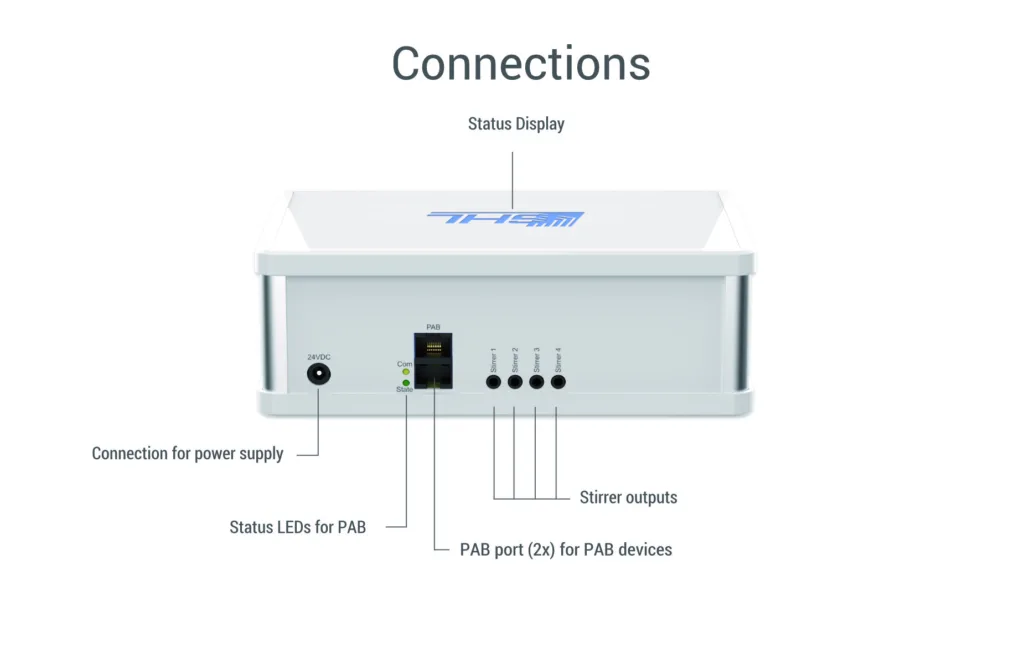

GHL Doser 2.2 Extension (EXT)

Expand Your System with Ease

Add additional dosing units to your Stand Alone Doser or control the Extension Doser directly with a ProfiLux Controller.

Communication is interference-free and highly reliable thanks to the GHL PAB (ProfiLux Aquatic Bus) and robust PAB cables.

GHL Doser 2.2: Quiet – Efficient – Reliable

Features at a Glance

Refilling and changing of small amounts of water.

The high-performance 24V stepper motors ensure accurate and reliable dosing, even for very small quantities (as little as 0.1 mL).

- Up to 150 doses per day in automatic mode

- Up to 8 individually programmable dosing times

- Each pump operates independently

- Adjustable dosing speed – up to approx. 45 mL/min

- Effortless setup with a built-in step-by-step guide

- Customizable categories for quick and easy data entry

- Automatic recording of test results from supported devices

- Visualize past and current values with a flexible, customizable chart

- Manually log test results from external test kits

- Record the addition of livestock or other changes in your tank

- Set reminders for important maintenance tasks like probe calibration or filter replacement

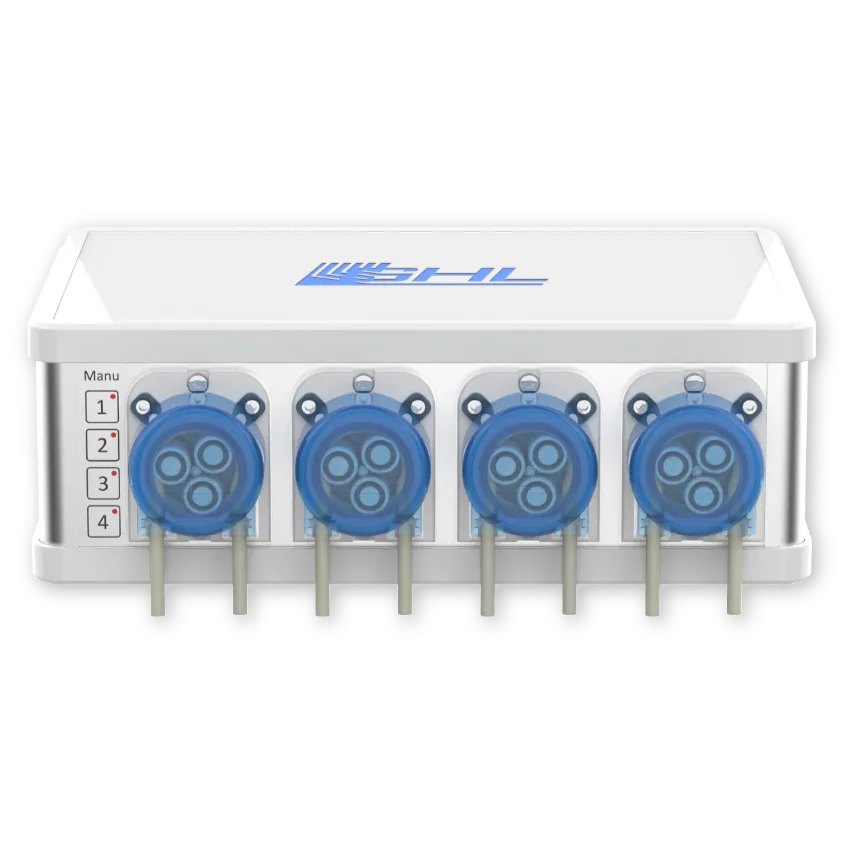

The illuminated GHL logo on the housing cover functions as a clear and intuitive status indicator. Different colors provide instant visual feedback on the current state of your system:

- White – Configuration mode

- Blue – Normal operation (no warnings or errors)

- Green – Dosing in progress

- Yellow – Warning: Liquid level below set threshold

- Red – Alarm: Liquid level critically low

Keep track and control of the liquid levels in your containers. An alarm signals that the minimum quantity has been reached.

- Magnetic Stirrers

Standalone model only:

- USB and WiFi

- Prepared for external GHL Control Pad

- Temperature sensors and Level sensors

The GHL Doser 2.2 offers flexible configuration options to fit a wide range of needs:

- Stand Alone (SA): Equipped with integrated control electronics, for independent operation.

- Extension (EXT): Operated via a GHL Doser 2.x SA, GHL Doser 2.x Maxi SA, or a ProfiLux Aquarium Controller.

Available with either a white or black cover to match your system’s look.

Getting started with the Doser 2.2 Stand Alone is straightforward. Configuration and daily operation are easily handled via the free GHL Connect app, the myGHL cloud platform, the integrated web interface, or the GHL Control Center (GCC) software for PC.

- The GHL Doser 2.2 is built from high-quality, long-lasting materials to ensure maximum reliability.

- Each dosing pump features chemical-resistant tubing and stainless steel motor shafts.

- The housing is made of rugged aluminum combined with durable plastic, providing solid protection and long service life.

Dimensions (without pumps): 220 x 150 x 76 mm (8.66″ x 5.91″ x 3″)

Precision Meets Quality – Down to the Smallest Detail.

Each pump can be operated manually using the push buttons on the front panel. This makes it easy to perform quick actions such as manual dosing or priming the tubing.

Maintenance and Wear Parts

The Doser 2.2 pumps are largely maintenance-free. For best performance, we recommend occasional cleaning to remove dust and other debris from the interior of the pumps. Do not lubricate the pumps under any circumstances.

Tubes, pumps, and motors are considered wear parts. Their lifespan depends on usage frequency, flow rate, and environmental conditions. If you notice issues such as reduced flow, loss of prime, leakage, or unusual operating noise—or if there is visible mechanical damage—the affected wear parts should be replaced.

Thanks to the maintenance-friendly design, all wear parts can be easily replaced. Replacement parts are readily available as accessories.

Last updated on: February 9, 2026