About Leakage Detection via the ProfiLux

The Leak detection feature can be used in various ways. The standard method involves the use of a Leak Interface and one or more Leak Sensors. If you’d like, you can also use this feature with GHL float and optical sensors. This is especially useful because you can use these sensors to prevent sump overflows, shut OFF the skimmer if the cup gets full or shut OFF a return pump if the sump water level gets too low.

If a leak is ever detected by the assigned sensor, the ProfiLux will trigger an alarm, notify you and take action if necessary (via socket control).

Before you begin

- If you are not familiar yet with the operating concept of the ProfiLux Controller, we highly recommend to first read the Knowledgebase Article ” How the ProfiLux Controller works “. It gives you an understanding of the basics and the operational concept of the controller.

- Make sure you have all the correct parts on hand. (See also list below)

Leak detection (Option 1)

| You will need… |

| 1x Leakage interface (PL-0851) |

| Leakage sensor (PL-0850) |

| Optional: Level sensor splitter cable (PL-0081) |

Leak detection (Option 2)

| You will need… |

| 1 GHL Level sensor; float (PL-1889) or optical (PL-1890) |

| Matching bracket for float (PL-0080) or optical sensor (PL-0723) |

| PL-LF-Base2 assembly rod (PL-1095) |

| Optional: Level sensor splitter cable (PL-0081) |

The PL-LY-Splitter Cable (PL-0081) enables you to connect two sensors to one level port.

In order for you to setup Leakage Detection on a ProfiLux Mini or Light controller, you will need the ProfiLux Mini / Light Adapter (PL-2024). This accessory is sold separately and can be found at the GHL store or GHL USA store.

With this accessory in-hand, you can take the included cable and connect it to the adapter (port labeled ProfiLux). Take the other end of the cable and connect it to the Black port as indicated below. Afterwards, you can connect your level sensor to the adapter, then follow the steps shown in Create the Leakage Detection function.

If you wish to expand the leakage detection area, simply daisy chain multiple leak sensors together. All leak sensors connected to a Leak interface will react as a single unit. By default, if any of these sensors detect conductive water, the P4 / P4e / Mini / Light controller will notify you of a leak and shut down assigned powerbar outlets.

In order to setup independent leak reactions, you will need a separate Leak interface.

For example, let’s say you wanted to have a leak sensor placed on top of a skimmer cup to prevent cup overflow and also wanted to have a leak sensor placed near the display tank. If you DO NOT want these sensors to react together, you will need 2 Leak interfaces for independent control.

Connect your GHL Level sensor to an available level port

You can find level ports on your ProfiLux Controller (starting with model 3), the Expansion Box, or an Expansion Card.

Connecting to ProfiLux:

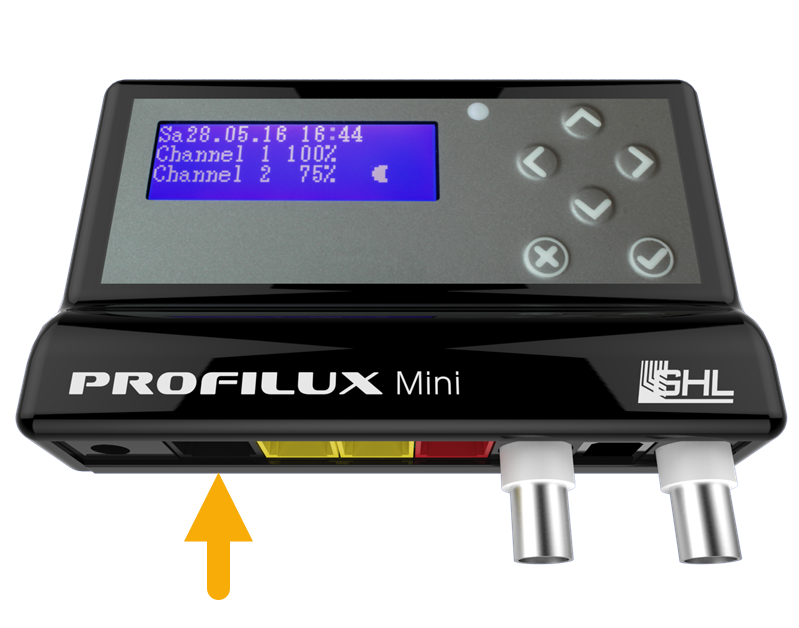

Take note which color port on the ProfiLux you are connecting the sensor(s) to

- Purple port: Level 1 / 2

- Green port: Level 3 / 4

If a single sensor is connected directly to a Level-port, the Level sensor will be assigned to the first number of that Level-port.

For example, if a single sensor is connected to Level 1/2, the sensor would automatically be assigned as Level sensor #1.

Level ports on the ProfiLux Controller

Connecting to an Expansion Card or a Expansion Box

If you are connecting the sensor(s) to an Expansion Card or Expansion Box, the Level-port numbering will continue beyond Level 3 / 4.

- For example, if you have a PLM-4Level Expansion Card, the Level-port numbering would be 5 / 6 for one port and 7 / 8 for the second port.

- If you do not have any Level-port expansion cards on the P4 / 4e and instead have an Expansion Box 2, Level 1 / 2 on the EXB2 would actually be Level 5 / 6.

Expansion Card PLM-4LEVEL with 4 Level-ports

Expansionbox 2 for ProfiLux

- and starts with the sensors permanently installed in the ProfiLux,

- then the sensor inputs of expansion cards (if available) follow,

- next, the fixed inputs of the first Expansion Box are counted,

- then the sensor inputs of expansion cards in the first expansion box.

- The numbering of sensor inputs of further Expansion Boxes is continued with the same system.

Create the Leakage Detection function

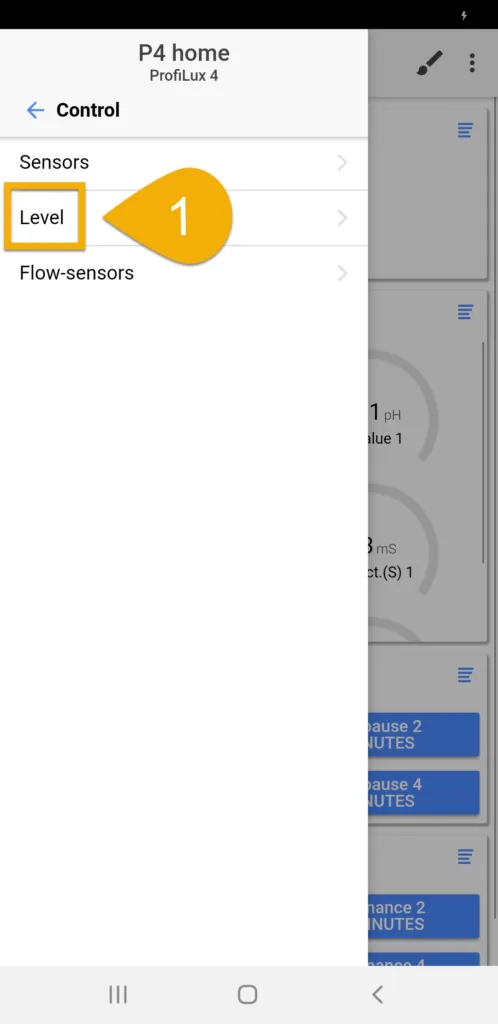

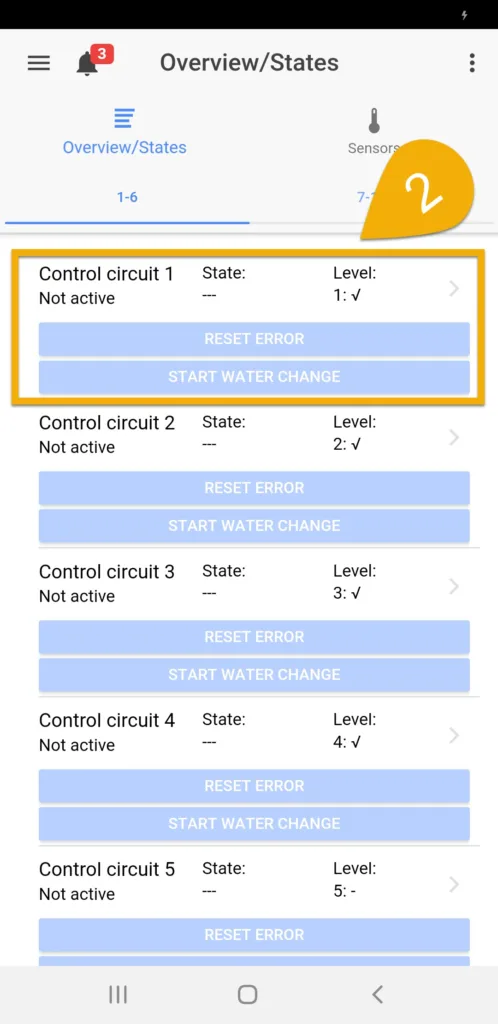

- Press the Menu icon, select Control, select Level

- Select an unused CONTROL CIRCUIT

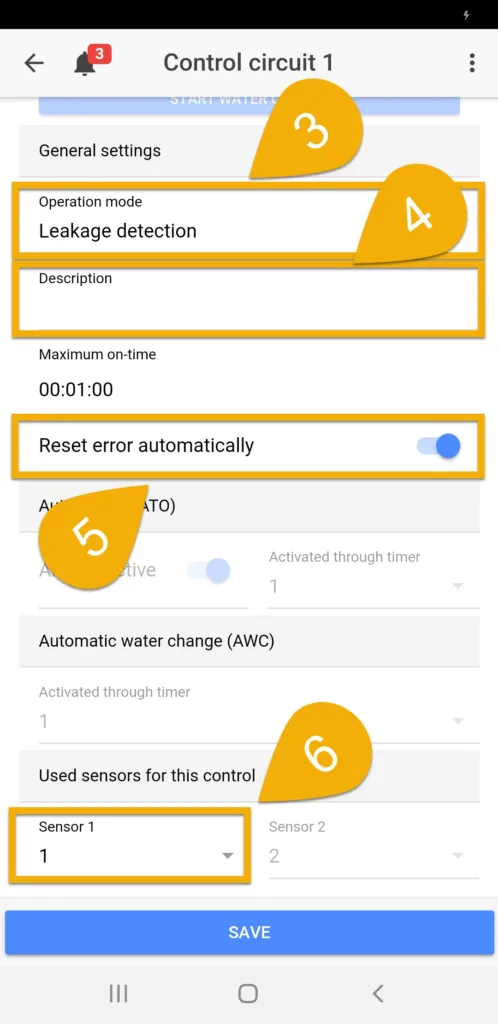

3. Set the Operation mode to Leakage detection

Maximum on-time is not involved here. No changes need to be made.

4. Type-in a description; Leak detection (Sump)

5. Select if you want the alarm to be reset automatically after being triggered. If enabled, the alarm will reset after normal conditions are detected (Recommended).

If left disabled, the alarm will remain until manually reset.

6. Select the sensors that will be used for this function, then press SAVE

For example, if you have a Leak interface or other sensor connected to the Level 1 / 2 port without a splitter cable, select (1).

If you are using a splitter cable on Level 1 / 2 and already have Level 1 assigned, select (2).

Using a float or optical sensor as a low-level switch for a return pump?

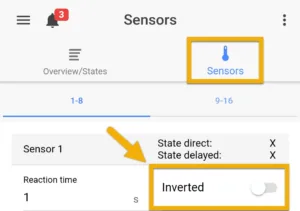

If you are using this feature for the purpose of shutting down your return pump if the sump water level gets too low, you MUST invert the reaction of the sensor. To do that, press the back-arrow, select the Sensors tab and set invert the reaction of the desired sensor, then press SAVE.

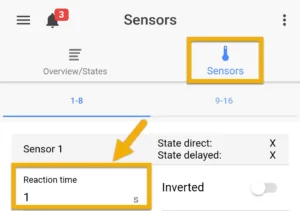

Want to delay the reaction time of a sensor?

Delaying the reaction time of a sensor can prevent the sensor/outlet from switching ON/OFF too often. If you need to delay the reaction of a level sensor, press the back-arrow, select the Sensors tab, specify the Reaction time of the selected sensor, then press SAVE.

Assign the Leakage Detection function

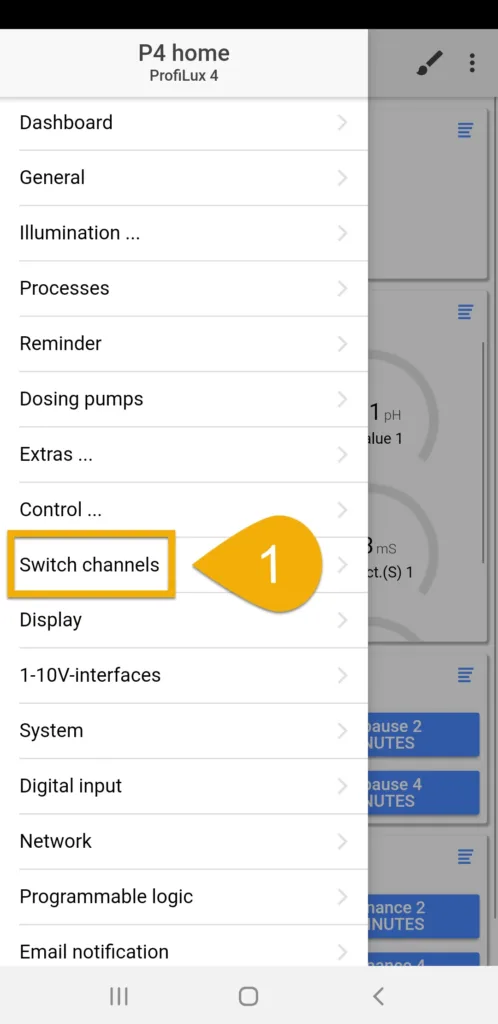

1. Press the Menu icon, press the back-arrow, select Switch channels

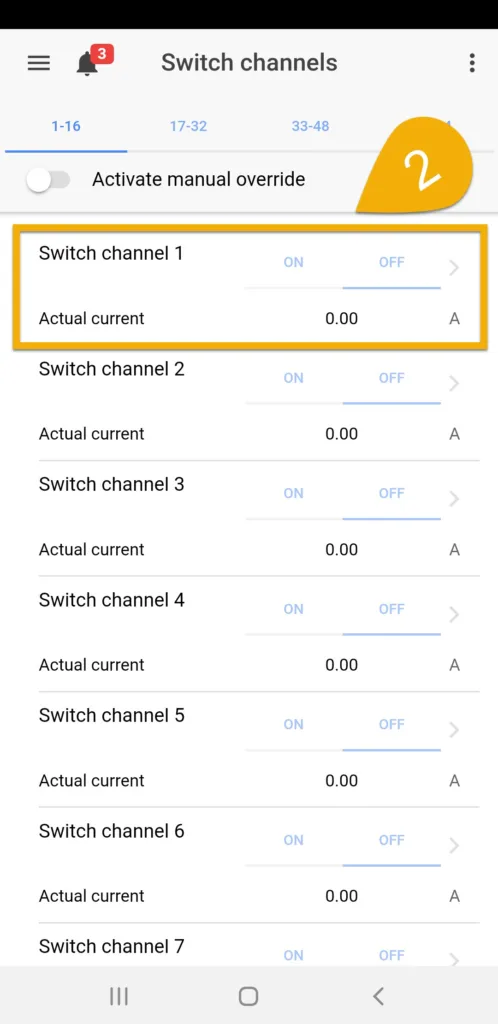

2. Select the switch channel(s) (Powerbar outlet(s)) that you want reacting to this leakage function

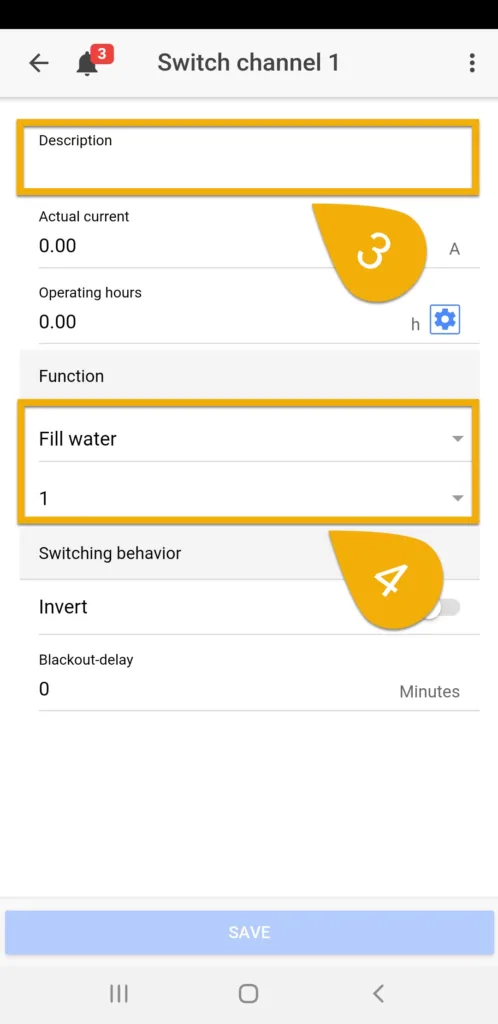

3. Type-in a description

4. Set the function to Fill water and select the Control Circuit number you used when you created the leak detection function, then press SAVE

For example, if you created the function on Control circuit 1, set the function to FILL WATER 1. If Control circuit 2 was used, set the function to FILL WATER 2.

5. Repeat steps 2 – 4 as necessary

NOTE

By default, the assigned switch channel will stay ON with this function. When a sensor detects a leak or a sensor is triggered, the assigned switch channel will turn OFF until the alarm is reset or problem is solved.

For those using a float or optical sensor for their return pumps, since the sensor reaction is inverted, the switch channel will stay ON when the sensor is in the water and turn OFF when it is no longer in the water.